Why choose this apprenticeship?

- STRONG INDUSTRY PARTNERSHIPS – Benefit from a programme built to meet the rigorous standards of the Manufacturing Engineer (Degree) apprenticeship, developed in close collaboration with industry. University College Birmingham leverages employer-led funding to deliver cutting-edge, industry-informed training, including specialist battery technology learning supported by Jaguar Land Rover (JLR) — giving you skills that are directly relevant to today’s advanced manufacturing sector.

- PROFESSIONAL RECOGNITION – This degree apprenticeship is aligned with the Institution of Engineering and Technology (IET), giving you a clear pathway towards achieving Incorporated Engineer (IEng) status — a nationally recognised mark of professional competence that can enhance your career progression and earning potential.

- SPECIALIST FACILITIES – Gain hands-on experience using our specialised labs, which include our Advanced Manufacturing Festo facility located in Camden House. Master industry-standard software for simulation and analysis, including SolidWorks, Fusion 360, ANSYS, and MATLAB, while completing compulsory modules such as Smart Manufacturing, Mechatronic Systems, and Industry 4.0 Manufacturing.

- CAREERS AND FLEXIBILITY – Develop key professional skills for roles such as Automation Engineer and Process Engineer, with flexible study options and the opportunity for an optional placement year to boost your experience and employability.

Our facilities

Advanced Manufacturing Festo facility: a specialist training space that uses industry-grade automation technology to replicate real manufacturing environments and prepare you for Industry 4.0.

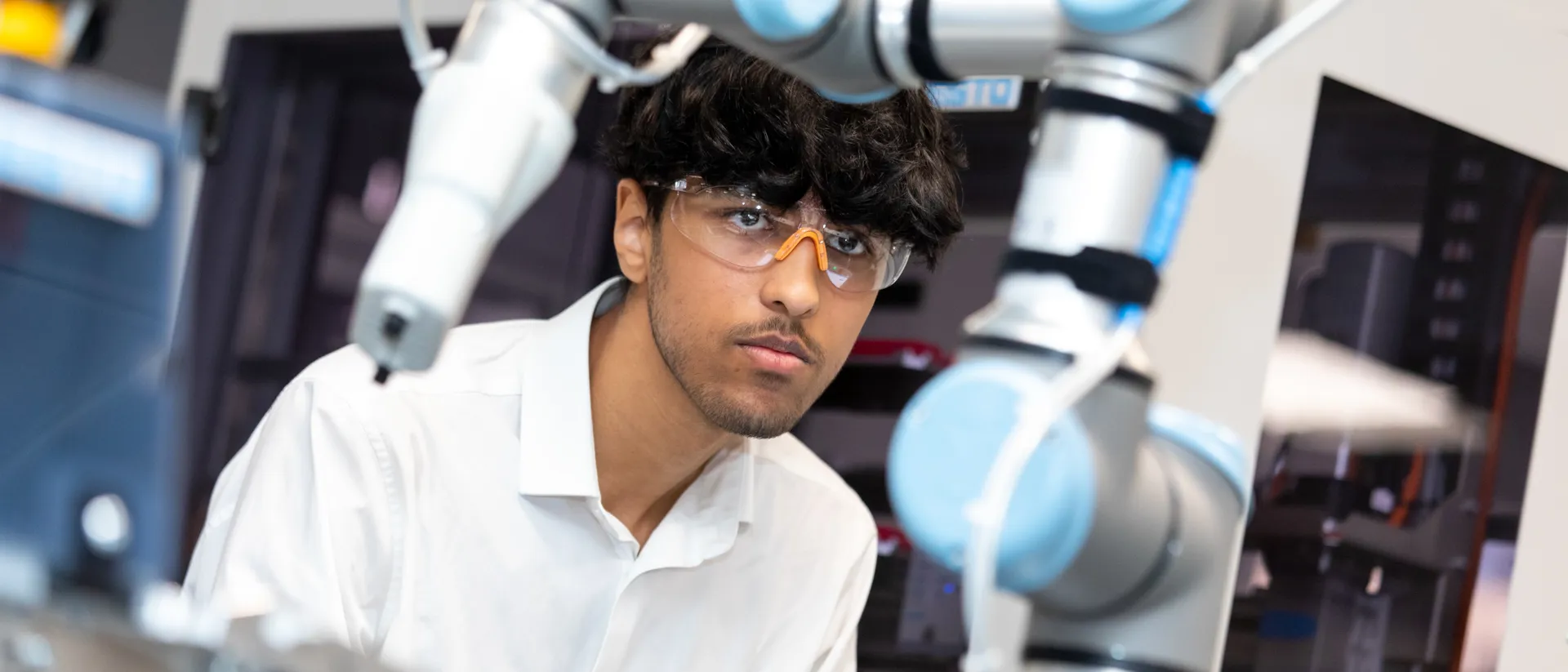

Mechatronics and Robotics Labs: featuring key equipment such as robotic arms, actuators, and sensor kits, giving hands-on experience in automation, robotics and mechatronics.

Mechanical and Material Testing Labs:These labs support core engineering analysis with equipment such as universal testing machines, hardness testers and microstructure analysis tools.

Thermodynamics and Fluid Mechanics Labs: supporting hands-on learning with equipment such as turbines, pumps and fluid flow apparatus.

Design and Modelling Software: including SolidWorks, AutoCAD, Fusion 360 and CATIA, used for 3D modelling, engineering drawings and technical documentation.

Simulation and Analysis Tools: such as ANSYS, Abaqus, COMSOL and SolidWorks Simulation, enabling structural, thermal and fluid analysis through FEA and CFD.

Programming and Control Systems: using MATLAB, Simulink, Python/C++, LabVIEW, and platforms like Arduino and Raspberry Pi for automation, control and mechatronics projects.

Materials and Project Management Software: including Ansys Granta Selector for materials selection and tools like Microsoft Project or Asana to support team-based and final-year projects.

Course breakdown

- Core Modules

Level 4

CAD Design

Computer Aided Design (CAD) is one of the most important disciplines in engineering. This module will provide the foundation and practical skills necessary to utilise an industry-standard CAD solution for designing an electromechanical product. You will learn how to create 3D solid models, create and analyse fully working assemblies, electric schematics and 2D orthographic drawings. You will also learn how CAD data is crucial to an engineering company and how it forms part of an end-to-end business process, where CAD data serves as the foundation for the virtual prototype. The module is delivered using a mix of lectures, self-guided study, and tutorials.

Engineering Mathematics

A thorough understanding of mathematical principles is essential in engineering. This module will ensure that you will have the required mathematical tools to complete the remaining modules within the BEng programme. The module will also provide the key mathematical principles that will help with your future engineering career. The module is delivered through a combination of lectures, self-guided study and tutorials. The module will cover matrix methods, probability and statistics, vectors and sinusoidal functions, complex numbers, calculus and numerical methods.

Fluid Power Principles and Applications

This Pneumatics and Hydraulics module covers fluid power systems in modern industry, with a focus on hydraulics and pneumatics. You will learn about the generation, control, and movement of mechanical components through pressurised fluids in enclosed systems. Supporting you to develop both theoretical knowledge and hands-on experience in designing and assessing pneumatic, hydraulic, electro-pneumatic, and electro-hydraulic systems.

Fundamentals of Engineering Mechanics

A thorough understanding of mechanical principles is essential for engineers to design and manufacture the products that surround us. The knowledge and application of these mechanical principles is still the essential underpinning science of all machines in use today or being developed into the latest technology. Modern engineering systems and products rely on static and dynamic principles to function effectively. Even systems that appear to be entirely electronic have a physical presence governed by the principles of statics. In this module, you will be introduced to the essential mechanical principles associated with engineering applications, such as: Behavioural characteristics of static, dynamic, and oscillating engineering systems, including shear forces, bending moments, torsion, linear and angular acceleration, conservation of energy and vibrating systems; and the movement and transfer of energy by considering parameters of mechanical power transmission systems. The module is delivered using a mix of lectures, self-guided study, and tutorials. On successful completion of this module, you will be able to explain the underlying principles, requirements, and limitations of mechanical systems

Materials Science and Engineering

The Materials Science and Engineering module introduces students to the fundamental properties, behaviour, and selection of engineering materials, including metals, polymers, ceramics, and composites. It emphasises the relationship between material structure, processing, and performance, enabling you to design and select materials for diverse mechanical engineering applications.

Software Applications

Software applications play an important role in accelerating innovation in engineering. Through simulation, designs can be optimised, and products can be virtually tested to determine key design parameters such as stress, strain, deflection, and factor of safety. Industry standard programming and numeric computing platform models can also be used to create and analyse models. In this module, you will use industry-standard 3D design software to develop engineering models and then analyse the products using the basic features of Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD). You will also use an industry-standard programming and numeric computing platform to create models for further analysis. The overall aim of the module is to introduce the basic concepts of software applications available to assist engineers throughout the product lifecycle. The module is delivered using a mix of lectures, self-guided study, tutorials, and group projects.

Level 5

Mechatronic Systems

Mechatronic systems are all around us. In our home appliances, in our cars, in our offices and on the factory floor. Mechatronics has been defined by the IEEE as “The Synergistic integration of mechanical engineering with electronics and intelligent computer control in the design and manufacturing of industrial products and processes.” That is, it encompasses aspects of diverse disciplines, including mechanical, electrical, electronic, computer, and control engineering, resulting in an overall integrated system. Leading mechatronics system engineers will possess skills across all these different engineering disciplines, and be able to view any solution holistically, rather than just as a collection of individual parts. This module will give you the skills to take a “system level” view of a system and break it down into appropriate mechanical, electrical and software components to allow you to design a system to achieve a given, integrated function

Renewable Energy and Sustainability

If the governments of the world are to tackle the problems of global warming and efficient use of renewable energy, engineers are key to solving them. Everything a professional engineer does affects these areas, as it is they who design, test, and manufacture products that use energy and contribute to global warming. A motor vehicle is a prime example. Indeed, the design of a product alone will determine approximately 80% of how that product will contribute to global warming and what happens to it at the end of that product’s lifetime. Energy use is a major contributor to global warming and engineers are pivotal in developing new renewable energy technologies. The Renewable Energy and Sustainability module aims to provide you with a wide understanding of societal pressure and the issues that face businesses and consider this from an engineering perspective. It will provide you with an understanding of the three pillars of sustainability and how business is affected by engineering decisions related to sustainability and energy use as we move towards a circular economy. The areas studied in this module include renewable energy use in comparison to fossil fuel use, environmental issues, environmental legislation, sustainable engineering, and whole-life cycle assessment of a product. Emphasis is placed on the general engineering sectors with consideration of the life cycle assessment of a simple product.

Smart Manufacturing

Smart factories utilise smart manufacturing processes which are enabled by the use of modern technologies such as the Industrialised Internet of Things (IIoT), artificial intelligence (AI), web-based data exchange, cloud computing and closed-loop data analysis. The smart manufacturing facility will utilise machinery and manufacturing systems that can exchange data to improve manufacturing processes and productivity. In this module, you will learn about the different areas of smart manufacturing and how the smart factory can benefit from using digitised manufacturing systems. You will consider the benefits of using smart manufacturing and the technologies used. This programme will include links to other modules, such as Industry 4.0 and the Internet of Things (IoT). You will identify the use of applications, including wireless connection, sensors and data collection. The module will also include monitoring the production environment in terms of production processes and predictive maintenance of equipment. You will identify the need for machine learning to optimise production processes, reducing energy consumption and increasing environmental benefits.

Systems and Control Principles

This module will provide you with a comprehensive understanding of the principles and techniques used in modern control systems. You will explore the mathematical models that describe dynamic systems, learn about the characteristics of control systems, and understand how to design controllers to regulate system behaviour. Key topics include system representation, stability analysis, control techniques such as PID control, frequency response, and state space analysis. This module includes practical lab sessions that provide hands-on experience with control systems design and implementation. By the end of this module, you will have acquired the necessary skills to analyse and design control systems, which are crucial for various engineering disciplines.

Thermofluid Mechanics

When working in Electromechanical Engineering, you will need knowledge of the principles of fluid mechanics and the techniques that are needed to predict the behaviour of fluids in a range of engineering applications. This module will provide you with knowledge of the principles applied to fluid mechanics and how to use techniques that predict, analyse and control the behaviour of fluids in given engineering applications. You will also study thermodynamics and how the Laws of Thermodynamics are applied and analysed by mathematical modelling for a range of thermodynamic systems.

Virtual Engineering and Simulation

Virtual engineering and simulation play an important role in accelerating innovation in engineering. Through simulation, designs can be optimised, and products can be virtually analysed to determine key design parameters such as stress, strain, deflection, and factor of safety. Assemblies can be simulated to analyse motion studies and further optimise the kinematic operation. In this module, you will utilise industry-standard 3D design software to develop electromechanical products and then analyse them using Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) techniques. You will explore the underlying mathematical models that facilitate FEA and CFD, and explore how the use of simulation tools can improve the time to market for products. The overall aim of the module is to introduce the basic theories of FEA and CFD techniques. The module also requires you to work in a group to solve a real-world engineering problem. The module is delivered using a mix of lectures, self-guided study, tutorials, and group projects.

Level 6

Advanced Manufacturing Systems

The Advanced Manufacturing Systems module examines the integration of modern technologies, including automation, robotics, and data-driven decision-making, into manufacturing processes. It equips students with the skills to design, analyse, and optimise advanced systems for efficient and sustainable production in various industries.

Independent Project

The engineering independent project provides an opportunity for you to work independently and investigate a topic in electromechanical engineering. It enables you to conduct a detailed and in-depth study of a topic within your own field of interest. The project will enable you to consolidate learning within other areas of your degree programme and strengthen them through further independent study. The engineering Independent Project is a module where you will conduct a detailed study and demonstrate your ability to research and critically review the literature. You will further analyse a problem within your area of engineering interest and reflect on the project findings. These are essential skills required to gain employment within the engineering sector. Your project will be presented in a portfolio format, accompanied by detailed documentation that evidences project planning for the initial topic and a final project report, which details the concept and work undertaken, outlining the project outcomes.

Industry 4.0 Manufacturing

Industry 4.0 provides a digital transformation for modern manufacturing companies on a global scale. It primarily integrates automation and data exchange technologies within the manufacturing industry. This requires the industrial environment to be fully digitalised by connecting engineering development, manufacturing environments and the supply chain to digital information systems and processes. In this module, you will integrate the modules studied in this programme, such as Smart Manufacturing and the Internet of Things (IoT), as well as others that involve digital systems within the manufacturing environment. You will be introduced to the principles of Industry 4.0, including the integration of automated systems and the exchange of data in the manufacturing environment, enabling the utilisation of flexible manufacturing systems and optimised production. Practical work will require you to develop a web-based application that enables a device or system to sense, monitor, and control operations.

Internet of Things Operation and Control

We take “stand-alone” electronic devices for granted, now. Electronic security systems, domestic boiler control systems, temperature monitors, pacemakers, car engine management systems, the list is endless. But what if those devices could communicate their condition and even allow a user to configure them remotely via the Internet? A home alarm that the owner can set and check remotely? A boiler that the user could switch off remotely, as they were going to be away for a few days? A Pacemaker that could contact the health service if it detected an anomaly, and allow a remote physician to adjust it accordingly? A car that tells your local service centre when it detects a fault? This is the world of the Internet of Things, commonly referred to as IoT. This module will build directly on your knowledge gained from the Embedded Systems module and take your learning to the next level.

Project Management

In the working world, project management will require you to apply the skills necessary to run industrial projects. Skills such as time and resource management, teamwork, and communication are all essential for running projects, whether short-term or long-term, or for smaller projects that are managed simultaneously and in parallel. As an Engineer, you will need these skills as they are essential to the success of any engineering career. The module is practically based using case studies. You will produce a portfolio of work, participating in group projects and completing individual assignments. You will apply the skills and knowledge necessary for running a successful project. You will acquire knowledge of the theory and practice of sustainable Project Management, applying the principles to work from a project brief, making decisions, managing risks, using control techniques, and managing projects in engineering applications designed to challenge you.

Key information

Entry requirements

Academic: Apprentices on this programme must have a minimum of a Level 2 in maths and English. We can guide you through your Level 2 functional skills in maths and English if you don't already possess them. An initial assessment will be completed as part of your enrolment.

88 UCAS points –

A-levels: CCD (Engineering, Physics, maths ideally, but not mandatory),

BTEC: MMM (Including further maths unit),

T-level: Pass (core component grade C).

GCSE/IGCSE: Maths (9–4/A*–C) or Functional Skills Level 2.

Other Level 3 qualifications are also welcome.

All apprentices must be employed full-time and their employer must be willing to support them through the apprenticeship.

How to apply

To apply, you must already be employed, and your employer must agree to you completing this apprenticeship. Once this agreement is in place, please contact apprenticeships@ucb.ac.uk, who will guide you and your employer through the process.

Please do not apply directly to the University for this apprenticeship. If you have an enquiry, please reach out to our team.

Teaching and assessment

We use a wide range of assessment strategies to support all styles of learning, including:

- Lectures, tutorials, and seminars.

- Laboratory practicals and workshops, supported by cutting-edge teaching facilities and an Advanced Manufacturing Festo facility.

- Real-world simulations and computer practical classes.

- Problem-solving classes, example sheets, and research projects.

- Group and independent practical tasks.

- Directed reading and resource-based learning.

- Project supervision

Contact hours will typically be 12 hours per week.

You will need to dedicate approximately 20 hours per week to individual study time.

Assessment:

Estimated breakdown of assessment for this degree course: The assessment for the BEng Automated Manufacturing Engineering course is structured across three years with varying emphasis on different methods:

- 1st Year:

- Coursework – 71%

- Written Examinations – 29%

- Practical assessment – 0%

- 2nd Year:

- Coursework – 75%

- Practical Assessment – 13%

- Written Examinations – 12%

- 3rd Year:

- Coursework – 90%

- Practical Assessment – 10%

- Written examinations – 0%

The BEng Manufacturing Engineer (Degree) apprenticeship uses a rigorous End-point Assessment (EPA), which typically lasts six months. The EPA determines the overall apprenticeship grade—Fail, Pass, or Distinction.

The EPA is comprised of two assessment methods:

-

Project with Report, Presentation, and Questioning:

- The apprentice must complete a significant project that has a real business application and benefit.

- The project work should result in a report (maximum of 9,000 words, with 10% tolerance) and a presentation.

- The presentation and questioning session will last at least 60 minutes, comprising a 20-minute presentation and 40 minutes of questioning by an independent assessor.

-

Professional Discussion underpinned by a Portfolio of Evidence:

- This is a formal, two-way conversation between the apprentice and an independent assessor, lasting 60 minutes.

- The discussion gives the apprentice the opportunity to demonstrate occupational competence based on their Portfolio of Evidence, which must be compiled during the on-programme period and submitted at the gateway.

The degree must be completed, passed, and awarded alongside the degree-apprenticeship. To achieve an overall Distinction, the apprentice must achieve at least a Pass in the Project and a Distinction in the Professional Discussion.

Our teaching and assessment is underpinned by our Learning and Teaching Strategy 2025-2030.

Fees

As an apprentice, you won’t need to pay tuition fees. Both your employer and the government will cover these costs for you. This extends to degree apprenticeships as well, allowing you to gain valuable work experience and academic qualifications without tuition expenses.